This problem has plagued users for a long while now and is almost constantly an issue brought up on the LokSound groups.io forum. Guaranteed you'll see it brought up about every two or three days.

There are several reasons this could happen and the majority of them are easily remedied. There is a list of things that need to be checked and these are mentioned whenever the problem pops up.

- Make sure Drive Hold is not on (default F9)

- Ensure the Independent Brake is not on (default F10)

- Ensure the Automatic (Train) Brake is not on

- To learn how to implement the Train brake read this

- Ensure Reverser Center is not on (default F24)

- Make sure CV19 is set to 0 (not in advanced consist)

- By default, the sound files have a 3 second delay before they allow the engine to move

- Allows the engine sound to spool up before moving (because that's how prototypes work, read this)

- If you haven't turned off this delay, give it a little time to start moving

- A comment was left by a reader with a common sense check I should have mentioned. After checking the easy stuff, check the motor contacts (or wiring) make sure they are clean (in the case of contacts) or wired correctly (for wiring). Problems with wiring includes a wire where half or more of the individual threads of wiring have been cut through or broken or have a bad (cold) solder joint. Thanks to the reader whoever you are.

Recently, the author came across this problem in a couple of his locomotives and it always occurred when initially programming the decoder. It didn't matter if the engine was programmed from scratch or was a copy of a previously programmed engine with just the engine number changed. It happened in both instances and was always for a v5 decoder (that's what the author has) so, both 21 pin and micro decoders developed the problem.

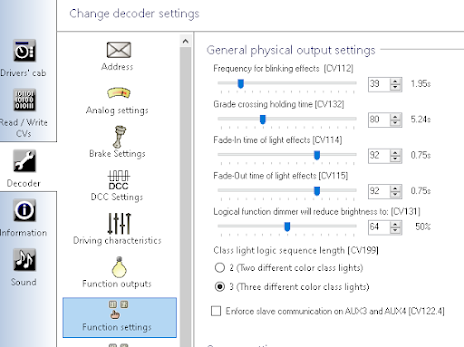

- Panes are the columnar selections on the left side of the LokProgrammer window. They start with Driver's Cab at the top and end with Sound at the bottom. Directly to the right of the Panes are the Sheets starting with Address. See figure 1.

- Sheets give you access to the individual CV settings of the decoder but they can also give you access to other things such as the individual sound slots on the Sound Pane. It depends on which Pane you select. It takes a little getting used to.

- Driver's Cab is a built in throttle which allows you to immediately test the changes you have made to CVs after Writing Decoder Data. It does not allow you to test any changes you have made to the Sound Pane though. Some changes there have to be burned to the decoder to hear them (the Simulator in the sound pane will allow hearing some changes but not all of them and that is beyond the scope of this discussion).

Fig 1 Panes, Sheets and CV access

Now For The Insidious One

Re-burning the unchanged original downloaded file from ESU (pure factory reset not a reset to previously programmed values) would clear up the problem so what did the author change that caused this?

Today it was decided he was going to take the time and trace the cause. One sheet at a time utilizing the Driver's Cab to test if the engine is running or not after changes and then go changed setting by changed setting on the particular sheet if the problem occurred.

This took some time. Brake Settings, Driving Characteristics, the various Function Sheets, all were fine. Motor Settings, WAIT!!! the engine refused to move!!! Now change by change until the author got to Motor Overload Protection. Long story short finally, checking the Enable motor current limiter would prevent the engine from moving! See figure 2.

Think! Why? This was an older HO KATO AC4400CW purchased at a swap meet and it had the same changes made as to a new one that was working. This makes perfect sense. The older motor needs more current than the new model and the protection wouldn't let it move because it was above the set limit.

Uncheck the Enable motor current limiter box, test, engine moves! Problem solved. Perhaps in the future (when there's time) some experimentation with this setting will show what's going on.

Don't forget this one after checking Drive Hold and all the different brakes don't fix the problem. Also remember that if after all of these checks are done and the engine still does not move, you probably have a blown drive circuit in the decoder and it requires a trip to Colorado for a fix. Remember that the ESU office has moved. It's no longer in Pennsylvania.

I hope this helps and I know it demonstrates what lengths you sometimes have to go through to isolate problems. Good luck!

<Update 2025-02-19>

Interesting development concerning these settings happened today. The author obtained a brand new CSX GP38-2 Atlas Master (new old stock) with the the older DCC/DC mother board controlled by a slide switch. The motherboard was removed and replaced by the new Athearn G67140 Genesis DC-21 Pin Motherboard for LEDs. A new ESU 21 pin v5 decoder was added and programmed.

Now for the fun! During the BEMF auto-calibrate (CV54=0, press F1) procedure, the author noticed that the engine was extremely sluggish although it did move. Testing the results, no matter how much the throttle speed was increased the engine refused to move at more than a crawl speedwise. The author went as far as re-burning the soundfile to the decoder, no joy. After some thought he remembered he had checked the Motor-overload-protection and also the Current-limiter-protection so, he unchecked them just to see if it had any effect and yes, you guessed it, the engine returned to normal running.

This one is a stumper!! These settings seem to have a lot more to do with the running of an engine than would be expected from their names and the experience discussed from the beginning of this post.

<Final Update 2025-04-17>

The author was finally able to reach ESU tech support and talked to Lee about these problems caused by Enable motor overload protection and Enable motor current limiter. According to Lee these two settings should be ignored. They were originally put into the programmer to help Rapido with some decoders they thought were having problems. Turns out it was the wonderful Chinese motors that were put into the engines (yeah, wonderful). So, accordingly, these settings are no longer needed. Lee stated (and I quote), "Frankly, I don't understand why ESU just doesn't remove these settings from the software".

So there you have it, leave these settings alone!

If you have an idea for a blog post here, let me know. If I can comment on it, I will or I'll see if someone else can and post it-